SERVICES

Aftermarket Solutions

Our team of engineers and technical field services personnel are able to develop solutions to optimize the performance of any OEM HRSG or WHB.

We often supply boiler products that require a high degree of technical integration to assure their successful implementation. These engineered solutions take into account process requirements, fabrication requirements, as well as onsite installation and constructibility challenges. Since we manufacture much of our own equipment, we understand how boilers are assembled and can be taken apart effectively.

Manufacturing

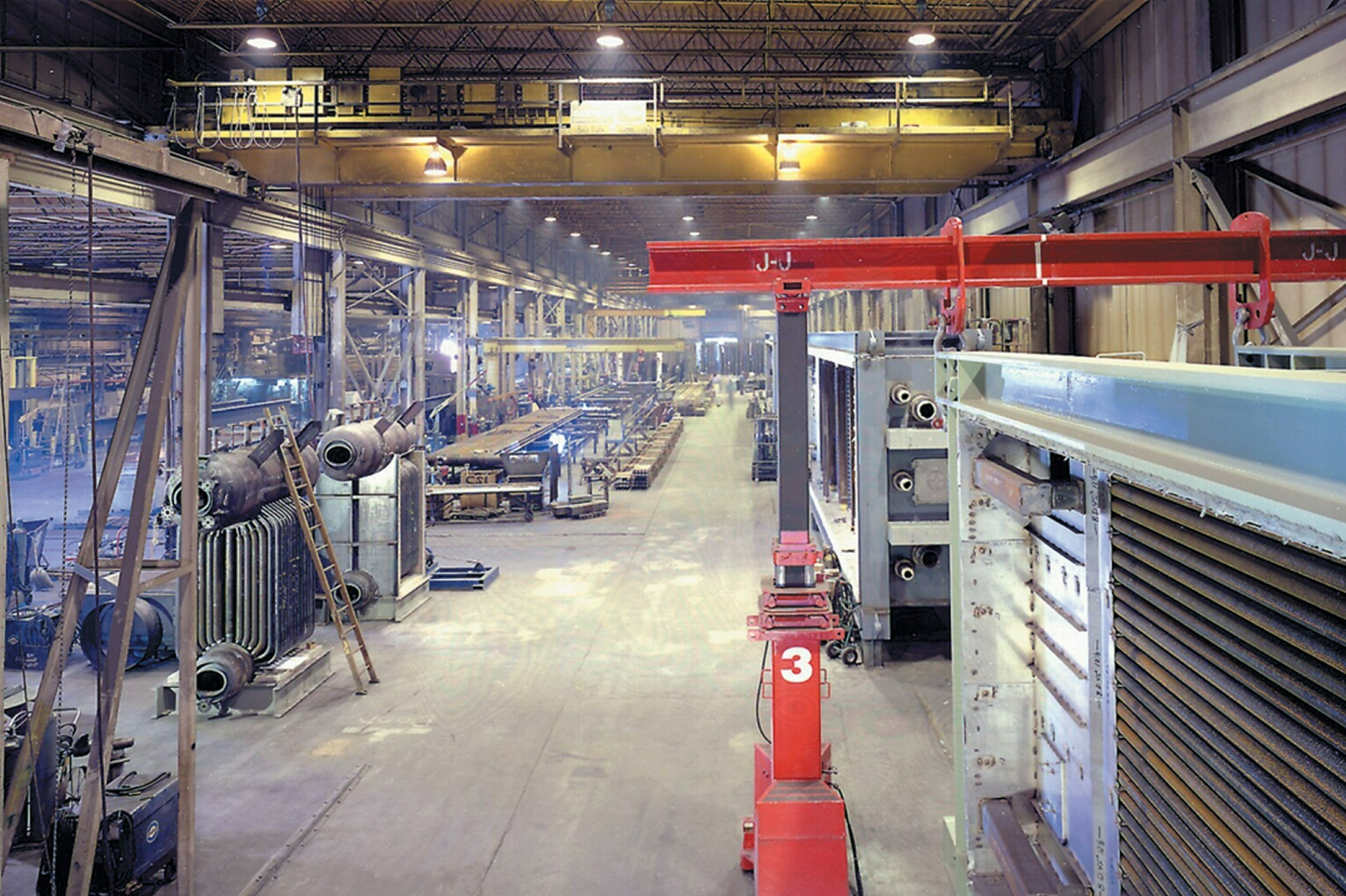

& Fabrication

Deltak offers a fully integrated fabrication solution to meet your project requirements. We’ve shipped more than 1500 boilers from our 65,000 sq ft custom-built facility, which offers us the first-hand experience to provide technical supervision and assistance to our local fabrication partners anywhere in the world.

- Tube Bending

- Header Fabrication

- Drum Drilling

- HRSG Harps/Panel

- WHB/HRSG Module Assembly

- Economizers

- Superheaters

- Reheaters

- Feedwater Preheaters

- Steam Drums

- Ducting

- Piping

- CO/SCR Catalyst Frames

Engineering/Field Services

- Equipment Inspections

- Visual External (Hot and Cold Inspections)

- Visual Internal Gas Side

- Visual Intneral Water Side

- Borescope / Videoscope

- UT Thickness Testing

- PT Testing

- FAC Risk Assessments

- Performance Analysis

- Rerate Studies

- System Redesign/Analysis

- Performance Modeling/Testing

- CFD/FEA Analysis

- Root Cause Investigation

- Outage Advisory Services (onsite)

- Construction/Commissioning Advisory Services

Heat Recovery Steam Generators

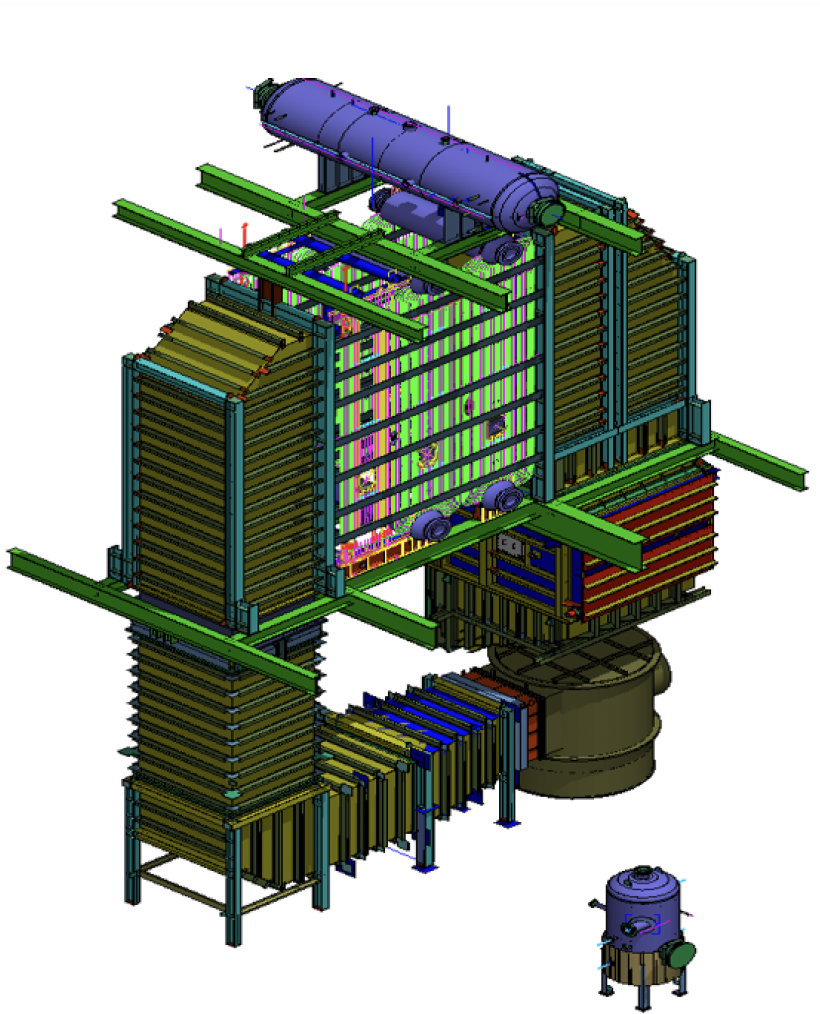

Deltak has engineered and manufactured more than 500 HRSGs behind gas turbines in the last 50 years. With experience across all levels of complexity and system types, Deltak has the experience for any application or type of project that may be required. Deltak offers a variety of constructability options depending on the size of the HRSG being supplied including but not limited to; replacement, inspection, parts, repairs, and maintenance.

Heat Recovery Boilers

Deltak’s 50+ years of engineering experience and advanced mechanical capabilities gives us the confidence to tackle our customer’s unique requests. With over 1200 custom-designed waste heat recovery units supplied to date, Deltak has unmistakable expertise in this industry. Utilizing different materials based on the situation, Deltak offers ASME Section I and VIII designed and fabricated watertube and firetube Waste Heat Boilers, to recover energy from flue gases created from various processes to lower gas temperatures for the next process or to simply produce steam.

Watertube Boilers

Designed similar to its HRSGs, but are often refractory lined, and typically have tubes that can handle dirtier flue gasses than in the power generation industry. Applications that would use a watertube waste heat boiler are typically refinery processes such as:

- Fluidized Catalytic Cracking

- Coke Calcining

- Sulphur Recovery

Firetube Boilers

Designed to have gas inside and water outside the tubes. These firetube boilers, or Process Gas Boilers (PGBs), are able to handle higher gas pressures and velocities than watertube boilers. Applications that would use a firetube boiler are typically chemical and incineration processes such as:

- Sulphuric Acid Recovery

- Hydrogen Processes

- Incineration

- Liquid/Gaseous Waste

Parts

Wide range of parts for Deltak and other OEM heat recovery systems including:

- Manway Gaskets

- Access Doors and Hardware

- Bare & Finned Tubes

- Tube Stubs for repairs (straight or bent)

- Return Bends

- Tube Plugs

- Steam Drum Internals

- Thermocouples

- Valves

- Pressure Gauges

- Fabric Expansion Joints

- Metall Bellow Casing Penetrations

- Inner Liner Components

- …and more!

Design &

Engineering

Services

We specialize in developing creative solutions to operational challenges, by leveraging our combustion turbine HRSG experience along with our waste heat boiler process experience. Solving difficult WHB process conditions aids in tricky HRSG applications, while HRSG cycling challenge solutions can be applied to WHB applications.

HRSG, Heat Recovery Steam Generator, Heat Recovery Steam Generation, Heat Recovery Steam Generator Maintenance, Heat Recovery Steam Generator Engineering, Heat Recovery Steam, Generator Inspections, HRSG Engineering, HRSG Replacement, HRSG inspection, HRSG parts, HRSG Repairs, HRSG Maintenance, HRSG Engineering, Steam Power Engineering, Boiler, Boiler Upgrade, Boiler Replacement, Flue gas Boiler, Flue Gas Boiler Maintenance, Flue Gas Boiler Engineering, Boiler Engineering, Boiler Maintenance, Boiler Inspections, Boiler Installation, Boiler Repairs, Heat Exchangers, Heat Exchanger Inspections, Heat Exchanger Tube Replacement, Heat Exchanger Tubes, Heat Exchanger Engineering